Product Name

Equipment standard specifications

| Item | unit | Machine specification |

|---|---|---|

| Machine standard | m/m | W1000 x H2000 x L5300 |

| Working scope | set according to product standard and production volume | |

| 1cycle film transfer distance | 1 - 8Cycle | |

| Molding & sealing die standard | 200m/m - 480m/m | |

| Maximum film forming length | 5m/m-90m/m (depends on product thickness) | |

| Upper and lower film width | Convert according to machine width | |

| Printing method | HOT | HOT printer & inkjet & thermal transfer printer available |

| Power electricity | 380V/4선식/60Hz | |

| Electric operation method | PLC | Touch Screen PLC control |

| Power consumption | Kw | 380V/4P/220V/3P 12kw or less (excluding vacuum pump) |

| Air consumption | L/Min | When 7Bar is applied, it consumes about 1,000-1,400 liters |

| Coolant consumption | L/Min | When 1Bar is applied, it consumes about 1,000-2,000 liters |

| Equipment weight | kg | 900 - 1200kg |

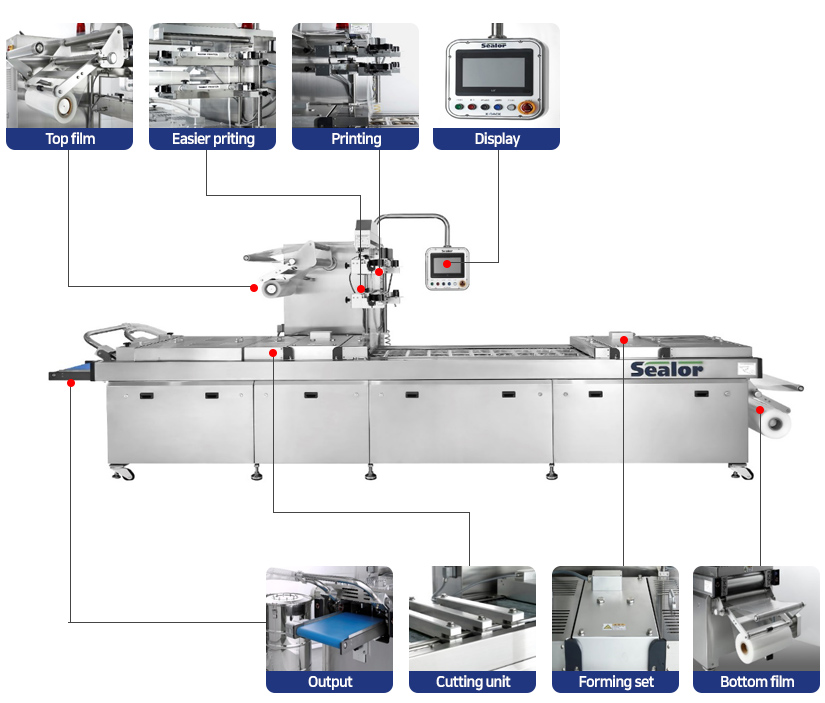

Facility features

- Two kinds of forming implementation (Flexible and Semi-rigid).

- Ink printer can be installed which can set general Hot Printer as default(optional).

- Open Print head type allows onvenient and quick exchange when replacing sealing film.

- The emergency stop button is applied to the front and rear for safety which is top priority.

- Detailed work settings such as temperature, vacuum degree, time, and sequence control for each packaged product are possible.

- Convenient operation such as touch-type display and detailed explanation of error occurrence.

- Applicable to accessory equipment according to various options such as labeler and filling machine.

Differentiation and strength

- Custom made tailored to the customer's site.

- Simple operation and repair.

- Granting functions according to customer's request.

Order of operation

1. loosen the bottom base film while it is wrapped around.

2. It is heated in Forming Die and molded into ‘Pocket’ or ‘Tray’ form.

3. The molded container is transferred automatically.

4. Put the product in the moved container.

5. The container is sealed by the top film.

6. When the air is degassed in the sealing position, it is sealed by heat and pressure and becomes a vacuum.

7. The vacuum sealed container is cut by the 'Cutting unit'.

8. It is released out of the facility by the transfer conveyor.

Application Product

- Packaging requiring gas barrier properties.

- Customized packaging according to product requirements.

- Increased productivity.

Various applications of thermoforming film

| Packing method | Item | Upper and lower film grade | Thickness(㎛) | Applicable product |

|---|---|---|---|---|

| 진공 방법 | General sterilization (100℃) |

Coextruded or laminate Sites films | 90~300 | Ham, sausage, meat, smoked duck, pork feet, soondae, etc. |

| Anti-Curl Film | 90~300 | Skewers, sliced ham, high-quality razor clam, bacon, etc. | ||

| Easy Peel Film | 90~200 | Ham, sausage, high-quality razor clam, bacon, etc. | ||

| Label suitable film | 120~210 | Barbecue | ||

| Sterile type (120℃, 30min) |

Coextruded or laminate Sites films |

120~200 | Tofu, fish cake, etc. | |

| Anti-wrinkle film | 120~200 | High quality fish cakes | ||

| Easy Peel Film | 120~200 | High quality fish cakes | ||

| Non-sterile | Coextruded or laminate Sites films | 120~210 | Pork feet, smoked duck, etc. | |

| High barrier film, high gloss film | 80~120 | Sliced ham and bacon | ||

| Freezing film | 100~170 | Frozen sausages, hamburger patties, etc. | ||

| Gas replacement | Non-sterile | High gloss, high barrier film | 500um | Bacon, sliced ham, fine sausage, baking confectionery |

| Anti-fog Film | 500um | Fresh meat | ||

| Easy Peel Film | 500um | Fresh meat, bacon | ||

| Reclosable Film | 500um | sausage | ||

| Skin Film | 500um | Fresh meat | ||

| Tray Film | 500um | Fresh meat, bacon, sausage, sliced ham |