- It is a new thermoforming vacuum packaging machine focused on consumer convenience that considers efficiency and economy based on the know-how of K-PACK’s ‘Sealor’ thermoforming vacuum packaging .

Equipment standard specifications

| Item | unit | Machine specification |

|---|---|---|

| Machine standard | m/m | W1000 x H2000 x L4500 |

| Working scope | set according to product standard and production volume | |

| 1cycle film transfer distance | 1 - 8Cycle | |

| Molding & sealing die standard | 200m/m - 400m/m | |

| Maximum film forming length | 5m/m-90m/m (depends on product thickness) | |

| Upper and lower film width | Convert according to machine width | |

| Printing method | HOT | HOT printer & inkjet & thermal transfer printer available |

| Power electricity | 380V/4P/220V/3P50/60Hz | |

| Electric operation method | PLC | Touch Screen PLC contro |

| Power consumption | Kw | 380V/4P/220V/3P 12kw or less (excluding vacuum pump) |

| Air consumption | L/Min | When 7Bar is applied, it consumes about 1,000-1,400 liters |

| Coolant consumption | L/Min | When 1Bar is applied, it consumes about 1,000-2,000 liters |

| Equipment weight | kg | 900 - 1200kg |

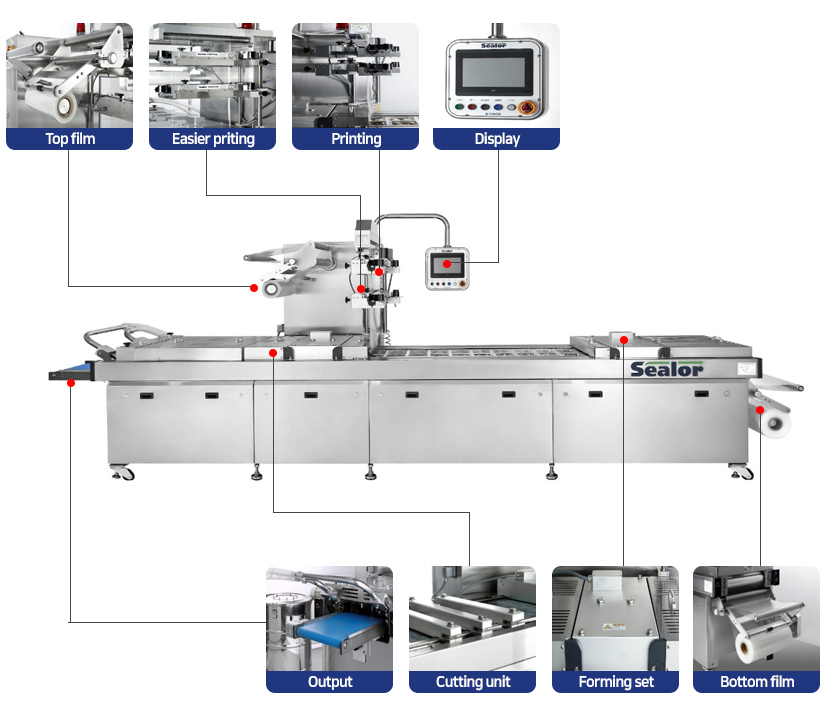

Facility features

- Pouches in manual packaging Forming automatically applied film.

- Two kinds of forming implementation(Flexible and Semi-rigid).

- Ink printer can be installed which can set general Hot Printer as default(optional).

- Open Print head type allows convenient and quick exchange when replacing sealing film.

- The emergency stop button is applied to the front and rear for safety which is top priority.

- Detailed work settings such as temperature, vacuum degree, time, and sequence control for each packaged product are possible.

- Convenient operation such as touch-type display and detailed explanation of error occurrence.

- Applicable to accessory equipment according to various options such as labeler and filling machine.

Differentiation and strength

- Maximize productivity.

- Customize according to the customer's site.

- Simple operation and repair.

- Granting functions according to customer's request.

Order of operation

- 1. loosen the bottom base film while it is wrapped around.

- 2. It is heated in Forming Die and molded into ‘Pocket’ or ‘Tray’ form.

- 3. The molded container is transferred automatically.

- 4. Put the product in the moved container.

- 5. The container is sealed by the top film.

- 6. When the air is degassed in the sealing position, it is sealed by heat and pressure and becomes a vacuum.

- 7. The vacuum sealed container is cut by the ‘Cutting unit’.

- 8. It is released out of the facility by the transfer conveyor.

Application (Application Product)

- Food and industrial packaging.

- Packaging requiring gas barrier properties.

- Customized packaging according to product requirements.

- Increased productivity.

[Various applications of thermoforming film]

| Packing method | Item | Upper and lower film grade | Thickness(㎛) | Applicable product |

|---|---|---|---|---|

| Vacuum method | Gas replacement (100℃) |

Coextruded or laminated film | 90~300 | Ham, sausage, meat, smoked duck, pork feet, sundae, etc. |

| Anti-Curl Film | 90~300 | Skewers, sliced ham, high-quality meat, bacon, etc. | ||

| Easy Peel Film | 90~200 | Ham, sausage, high-quality meat, bacon, etc. | ||

| Label suitable film | 120~210 | Barbecue | ||

| Sterile type (120℃, 30 minutes) |

Coextruded or laminated film | 120~200 | Tofu, fish cake, etc. | |

| Anti-wrinkle film | 120~200 | High quality fish cakes | ||

| Easy Peel Film | 120~200 | High quality fish cakes | ||

| Non-sterile | Coextruded or laminated film | 120~210 | Pork feet, smoked duck, etc. | |

| High barrier film, high gloss film | 80~120 | Sliced ham and bacon | ||

| Freezing film | 100~170 | Frozen sausages, hamburger patties, etc. | ||

| Gas replacement | Non-sterile | High gloss, high barrier film | 500um | Bacon, sliced ham, fine sausage, baking, confectionery |

| Anti-fog film | 500um | Fresh meat | ||

| Easy Peel Film | 500um | Fresh meat, bacon | ||

| Reclosable Film | 500um | sausage | ||

| Skin Film | 500um | Fresh meat | ||

| Tray Film | 500um | Fresh meat, bacon, sausage, sliced ham |

Application